Home » PRODUCTS » Specialized Drive » Packaging Industry

The HLP-SD100 series is a rewinding special drive, which built perfect coil diameter calculation, precise PID control, support a variety of incremental encoder, high closed-loop or open-loop torque precision, widely used in papermaking, printing, drawing machine, printing and dyeing and other high-end reeling application of equipment.

papermaking, printing, drawing machine, printing and dyeing and other high-end reeling application of equipment

|

Excellent control performance |

|

High environmental adaptability |

|

|

||

|

Inner special application | ||

|

|||

|

Excellent User Friendliness | ||

|

| Item | Specification | |

| Power supply | Supply voltage |

Single/three phase 200~240V -20%~+10%; Three phase 380~480V -20%~+10%; |

| Frequency | 48-62Hz; | |

| Max. imbalance | 3% ; | |

| Motor output | Output voltage | Three phase 0-100% of supply voltage |

| Output frequency | V/F : 0-400Hz , VVC+: 0-200Hz; | |

|

IO board control terminals

|

Input |

5 digital inputs (1 supports pulse input, pulse range: 1Hz~100kHz); 2 analog input,(1 supports 0~10V/-10V ~10V; other supports voltage/current signal; PG input terminal: support (Support open collector PNP output ; open collector NPN output / voltage output; push-pull output / linear drive output type;) |

| Output |

1 digital output (1 supports pulse output, pulse range: 1Hz~100kHz); 2 relay output; 1 analog output (1 can be selected as current output or voltage output via jumper switch). |

|

| Power supply |

1 +10V, max current output 10mA; 1 24V, max current output 200mA; |

|

| Communication | RS+, RS-, max baud rate 115200bit/s; | |

| Display | 8 segments, 5 numeric displays | Display frequency, warnings, status and so on; |

| Indicator | Light FWD, REV, HZ, A, RPM display various status of the drive; | |

| Data read-outs | Frequency setting, output frequency, feedback value, output current, DC link voltage, output voltage, output power, input terminals state, output terminals state, analogue input , analogue output, 1-10 fault records and accumulated working time etc.; | |

| Environment | Enclosure | IP20; |

| Ambient temperature | -10℃~50℃, derating use when over 40℃; | |

| Humidity | 5%-85% (95% without condensation); | |

| Vibration test | 1.14g; |

|

| Max. altitude above sea level | 1000m, derating use when more than 1000 meters; | |

| Motor cable length | Shield cable: 50 meters; Unshield cable: 100 meters; | |

| Others | DC choke | ≥37kW Built-in |

| Braking unit |

≤22kW Built-in |

|

| Main control functions | Control mode | V/F, Vector control; |

| Start torque | 0.5Hz 150%; | |

| Overload capacity | 150% 60s, 200% 1s; | |

| PWM switch frequency | 2k~16kHz ; | |

| Speed setting resolution |

Digital: 0.001Hz; Analogy: 0.5‰ of the max. operating frequency ; |

|

|

Speed open-loop control accuracy |

30~4000 rpm: tolerance±8 rpm; | |

| Speed close-loop control accuracy | 0~6000 rpm: tolerance±0.15 rpm; | |

| Control command source | LCP, digital terminal, local bus; | |

| Frequency setting source | LCP, analog, pulse, local bus; | |

| Ramp control | Selectable 4-speed steps ramp up and down times 0.05-3600.00s; | |

| Basic Functions | Speed Open-loop Control; Speed Close-loop Control; Process Closed-loop Control; Torque Open-loop Control; Torque Close-loop Control; AMA Function; Motor Magnetisation; Slip Compensation; Torque compensation; Automatic Voltage Regulation; V/F Control, DC Brake; AC brake; Speed Limit; Current Limit; Flying Start; Reset Function; Counter; Timer; | |

| Application Functions | Wobble Function; Jogging; Multi-speed Control via Digital input; SLC(including Order Control and Parallel Control); Mechanical Braking; UP/DOWN ; Catch up /Slow down; Relative Scaling Reference high speed pulse input/output; inner PID control; roll diameter calculation; Pre-drive etc. | |

|

Protection Functions |

Missing Motor Phase Protection; Low-voltage Protection; Over-voltage Protection; Over-current Protection; Output Phase Loss Protection; Output Short Circuit Protection; Output Grounding Fault Protection; Motor Thermal Protection; Live Zero Timeout Function; AMA Fails; CPU Fault; EEPROM Faults; Button freeze; Duplicate Fails; LCP Invalid; LCP Incompatible; Parameter Read-only; Reference Out of Range; Invalid While Running etc. | |

| Model | Input voltage |

Input current (A) |

Output current (A) |

Rated power (kW) |

Heat dissipating capacity (kW) |

Fan capacity (m³/h) |

Net weight (kg) |

|---|---|---|---|---|---|---|---|

| HLP-SD1000D7543 | 3×380-440V | 3.7 | 2.3 | 0.75 | 38.5 | 51 | 1.3 |

| 3×440-480V | 3.2 | 2.1 | |||||

| HLP-SD10001D543 | 3×380-440V | 6.4 | 4.0 | 1.5 | 49.0 | 51 | 1.3 |

| 3×440-480V |

5.5 | 3.6 | |||||

|

HLP-SD10002D243 |

3×380-440V | 8.9 | 5.6 | 2.2 | 65.2 | 51 | 1.3 |

| 3×440-480V |

7.7 | 5.1 | |||||

|

HLP-SD10004D043 |

3×380-440V | 15.8 | 9.9 | 4.0 | 122.9 | 51 | 2.0 |

| 3×440-480V |

13.6 | 9.0 | |||||

| HLP-SD10005D543 | 3×380-440V | 21.3 | 13.3 | 5.5 | 139.4 | 51 | 2.0 |

| 3×440-480V |

18.4 | 12.1 | |||||

| HLP-SD10007D543 | 3×380-440V | 28.3 | 17.7 | 7.5 | 211.6 | 68 | 2.5 |

| 3×440-480V | 24.4 | 16.1 | |||||

|

HLP-SD100001143 |

3×380-440V | 35.9 | 25.0 | 11 | 262.4 | 124 | 5.8 |

| 3×440-480V |

31.4 | 22.7 | |||||

|

HLP-SD100001543 |

3×380-440V | 43.4 | 32.0 | 15 | 339.3 | 170 | 5.8 |

| 3×440-480V |

38.8 | 29.1 | |||||

|

HLP-SD10018D543 |

3×380-440V | 51.5 | 38.0 | 18.5 | 418.0 | 230 | 8 |

| 3×440-480V |

46.1 | 34.5 | |||||

|

HLP-SD100002243 |

3×380-440V | 61.0 | 45.0 | 22 | 468.2 | 272 | 8 |

| 3×440-480V | 54.5 | 40.9 | |||||

|

HLP-SD100003043 |

3×380-440V | 73 | 61 | 30 | 676.3 | 303 | 19 |

| 3×440-480V | 64 | 52 | |||||

| HLP-SD100003743 | 3×380-440V | 72 | 75 | 37 | 795.0 | 374 | 22 |

| 3×440-480V | 65 | 68 | |||||

|

HLP-SD100004543 |

3×380-440V | 86 | 91 | 45 | 974.8 | 408 | 26 |

| 3×440-480V | 80 | 82 | |||||

|

HLP-SD100005543 |

3×380-440V | 110 | 112 | 55 | 1246 | 476 | 26 |

| 3×440-480V | 108 | 110 | |||||

|

HLP-SD100007543 |

3×380-440V | 148 | 150 | 75 | 1635 | 595 | 37 |

| 3×440-480V |

135 | 140 | |||||

| HLP-SD100009043 | 3×380-440V | 175 | 180 | 90 | 2204 | 646 | 60 |

| 3×440-480V | 154 | 160 | |||||

| HLP-SD100011043 | 3×380-440V | 206 | 215 | 110 | 2600 | 714 | 60 |

| 3×440-480V | 183 | 190 | |||||

| HLP-SD100013243 | 3×380-440V | 251 | 260 | 132 | 3178 | 850 | 60 |

| 3×440-480V | 231 | 240 | |||||

| HLP-SD100016043 | 3×380-440V | 304 | 315 | 160 | 3689 | 1029 | 99 |

| 3×440-480V | 291 | 302 | |||||

| HLP-SD100018543 | 3×380-440V | 350 | 365 | 185 | 4268 | 1190 | 99 |

| 3×440-480V | 320 | 335 | |||||

| HLP-SD100020043 | 3×380-440V | 381 | 395 | 200 | 4627 | 1292 | 99 |

| 3×440-480V | 348 | 361 | |||||

| HLP-SD100022043 | 3×380-440V | 420 | 435 | 220 | 4935 | 1411 | 99 |

| 3×440-480V | 383 | 398 | |||||

| HLP-SD100025043 |

3×380-440V | 472 | 480 | 250 | 5323 | 1564 | 250 |

| 3×440-480V | 436 | 443 | |||||

| HLP-SD100028043 | 3×380-440V | 525 | 540 | 280 | 6543 | 1700 | 250 |

| 3×440-480V | 475 | 490 | |||||

| HLP-SD100031543 | 3×380-440V | 590 | 605 | 315 | 7251 | 1870 | 250 |

| 3×440-480V | 531 | 540 | |||||

| HLP-SD100035543 |

3×380-440V | 647 | 660 | 355 | 7497 | 2125 | 250 |

| 3×440-480V | 580 | 590 | |||||

| HLP-SD100041543 | 3×380-440V | 718 | 745 | 415 | 8284 | 2380 | 250 |

| 3×440-480V | 653 | 678 | |||||

| 45kW & above will be developed later | |||||||

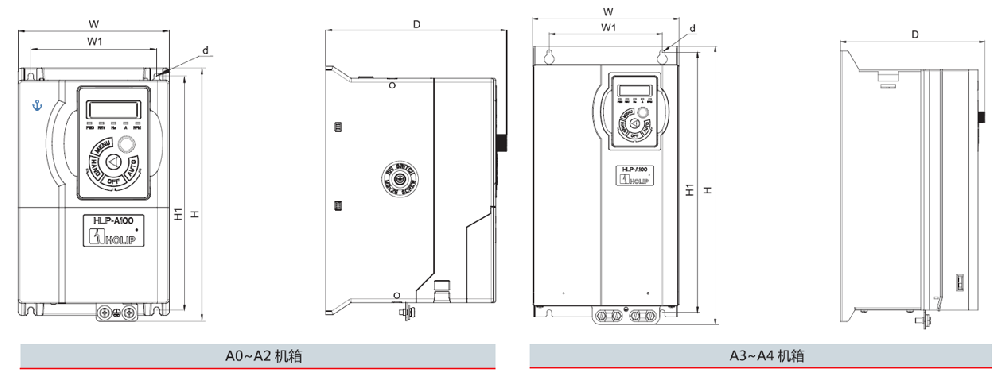

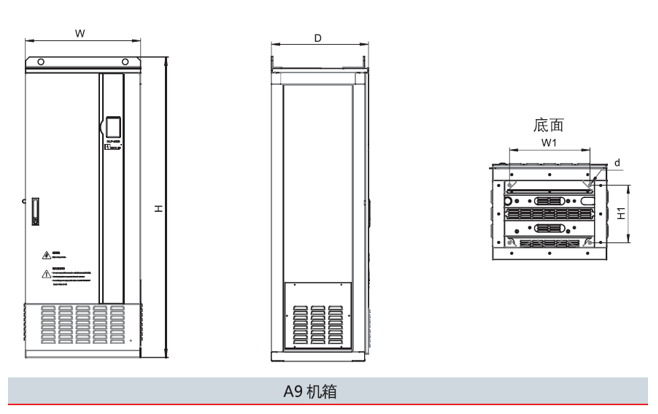

| Case | Power & Voltage | Dimensions(mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| 3x380-480V | W | H | D | W1 | H1 | W2 | d | |

| A0 | 0.75-2.2kW | 125 | 210 | 152 | 104 | 194 | - | 4.5 |

| A1 | 4.0-5.5kW | 145 | 250 | 167 | 124 | 230 | - | 4.5 |

| A2 | 7.5kW | 155 | 263 | 177 | 133 | 243 | - | 4.5 |

| A3 | 11-15kW | 192 | 365 | 189 | 150 | 340 | - | 6.5 |

| A4 | 18.5-22kW | 216 | 420 | 194 | 150 | 395 | - | 6.5 |

| A5-1 | 30-37kW | 292 | 517 | 229 | 240 | 492 | - | 9 |

| A5-2 | 45-55kW | 292 | 562 | 249 | 240 | 537 | - | 9 |

| A6 | 75kW | 292 | 665 | 277 | 240 | 640 | - | 9 |

| A7 | 90-132kW | 350 | 799 | 375 | 220 | 765 | 280 | 10.5 |

| A8 | 160-220kW | 486 | 900 | 390 | 345 | 863 | 410 | 10.5 |

| A9 | 250-415kW | 600 | 1568 | 509 | 424 | 304 | - | 15 |